Products

We offer vision inspection solutions for a huge range of plastic packaging. You cannot find the right vision system for your product?

Just contact us for a customized solution.

Our products

-

Medical Cap Vision System

1、Preparation stage, check whether the equipment is running normally;

2, sample testing, using standard samples to test machine performance;

3、Data analysis, analyze the testing data to ensure accuracy;

4、Results evaluation, according to the data to determine whether the machine is qualified;

5、Finally, issue a quality inspection report to record the whole process.

Learn more -

Medicine Bottle Vision System

1、Plastic bottles are transferred to the testing machine by conveyor belt.

2、Bottles are clamped by the special bottle clamping belt and transported forward.

3、Due to the speed difference, the bottle rotates, and when it passes through the optical imaging system, the imaging information is quickly obtained.

4、Computer compares with the stored standard model to determine whether it is qualified or not.

5、Notify the bottle pusher to push out the unqualified bottles, and the qualified ones continue to be conveyed.

Learn more -

Plastic Bottle Vision system

1、Plastic bottles are transferred to the testing machine by conveyor belt.

2、Bottles are clamped by the special bottle clamping belt and transported forward.

3、Due to the speed difference, the bottle rotates, and when it passes through the optical imaging system, the imaging information is quickly obtained.

4、Computer compares with the stored standard model to determine whether it is qualified or not.

5、Notify the bottle pusher to push out the unqualified bottles, and the qualified ones continue to be conveyed.

Learn more -

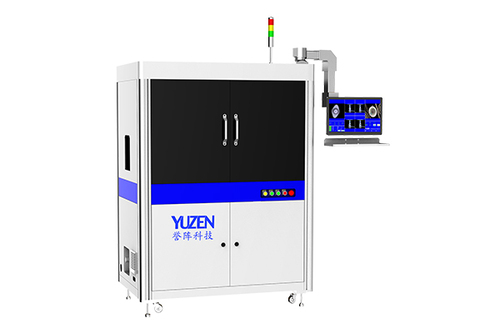

Cap Vision System

1、Preparation stage, check whether the equipment is running normally;

2, sample testing, using standard samples to test machine performance;

3、Data analysis, analyze the testing data to ensure accuracy;

4、Results evaluation, according to the data to determine whether the machine is qualified;

5、Finally, issue a quality inspection report to record the whole process.

Learn more -

Bottle Embryo Testing Machine

1、Place the preforms on the conveyor of the inspection machine;

2、when the preforms pass the sensor, the equipment will scan them;

3、The computer software in the inspection machine analyzes the scanning results and determines whether there are defects in the preforms;

4、If defects are found, the inspection machine will automatically reject the nonconforming products;

5、Through the above process, it can ensure that the quality of preforms meets the requirements.

Learn more -

In-mold labeling detection stacking machine

1、Preparation stage, check whether the equipment is operating normally;

2, sample testing, using standard samples to test machine performance;

3、Data analysis, analyze the testing data to ensure accuracy;

4、Results evaluation, according to the data to determine whether the machine is qualified;

5、Finally, issue a quality inspection report to record the whole process.

Learn more -

Large format inspection systems

1、 PDF· Yinhu Shenpin Wide Open Version Inspection System (S-Scan LNC)

2、flat plate version inspection system (S-Scan A2/A3/A4)

Learn more -

Containers Curved Surface Printing Vision Inspection System

1、Preparation stage, check whether the equipment is operating normally;

2, sample testing, using standard samples to test machine performance;

3、Data analysis, analyze the testing data to ensure accuracy;

4、Results evaluation, according to the data to determine whether the machine is qualified;

5、Finally, issue a quality inspection report to record the whole process.

Learn more -

Spray Pump Vision System

1 Testing machine supporting the material processing machine, mainly divided into three units: material processing unit, testing unit, bad product removal unit

2 System for full inspection of pump head appearance and components, equipped with HD color camera

3 Configuration Options: The number of cameras is 7-12, the accuracy is 0.1mm-0.3mm, and the speed is 120-300 / min

4 Applicable products: various specifications of pharmaceutical spray pump

Learn more