High precision. High efficiency.

Bottle Embryo Testing Machine

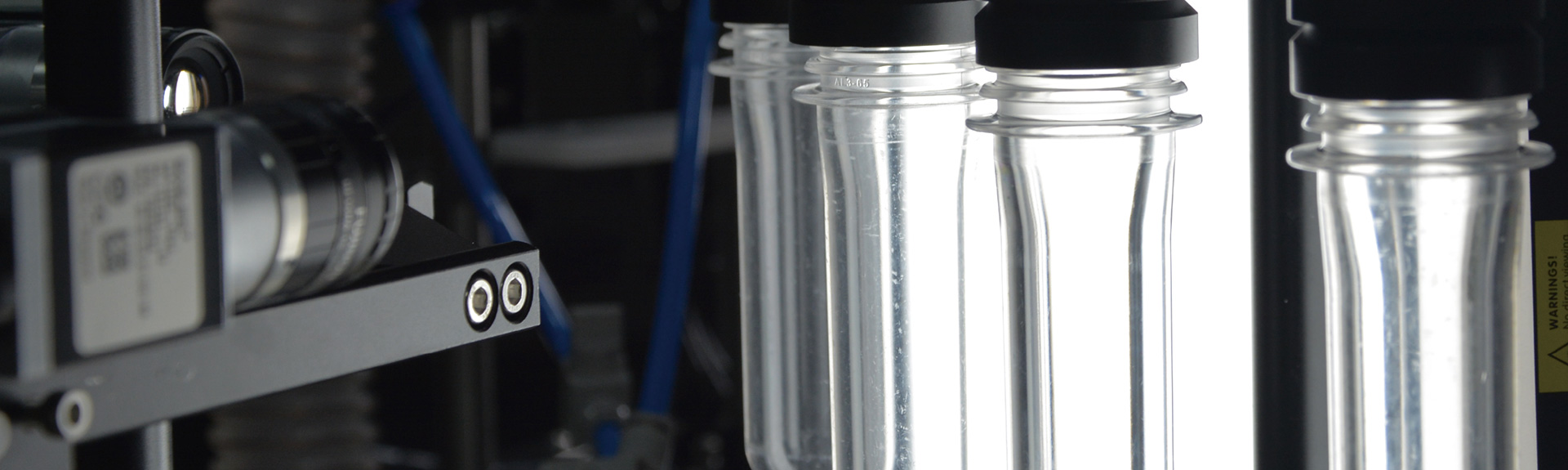

High-precision and high-efficiency preform inspection equipment. This inspection machine utilizes the core technology of YOOFUNCTION Technology, combining machine vision, artificial intelligence and big data analysis to provide comprehensive quality assurance for the production process of preforms. This equipment utilizes a high-resolution industrial camera and advanced image processing algorithms to inspect the surface quality of the preforms, and can quickly and accurately detect various defects, such as deformation, flying edges, black dots, bubble cracks, air bubbles, impurities and so on. This equipment adopts stable and reliable industrial-grade hardware and software systems with strong anti-interference ability and self-learning ability. Meanwhile, Goodwill also provides perfect after-sales service and technical support to ensure the long-term stable operation of the equipment.

At a glance

The unique main functions of the Bottle Embryo Testing Machine:

-

High precision detection

The detection accuracy is more accurate than the human eye detection.

-

High-speed continuous shooting

It can quickly capture the real-time state of the bottle embryo.

-

Multi-mode detection

Can detect a variety of defects in the bottle embryo.

-

Intelligent culling

Detected defects are automatically removed.

-

Remote debugging management.

Production state can be operated remotely over the network.

-

Easy to operate

Push-button operation, convenient and fast.

Key Components of Bottle Embryo Testing Machine

Do you want to learn more about the Medicine Bottle Embryo Testing Machine?

Understand the quality inspection process of Bottle Embryo Testing Machine

1、Place the preforms on the conveyor of the inspection machine;

2、when the preforms pass the sensor, the equipment will scan them;

3、The computer software in the inspection machine analyzes the scanning results and determines whether there are defects in the preforms;

4、If defects are found, the inspection machine will automatically reject the nonconforming products;

5、Through the above process, it can ensure that the quality of preforms meets the requirements.

Our customers' industries

FAQs about Bottle Embryo Testing Machine

-

The scope of defects detected by the Equipment Department?

What is the applicable product range of the equipment?

What are the application industries of the equipment?

Is the equipment easy to operate?

Contact us and find the best solution

Do you want to learn more about the implementation of current Industry 4.0 trends? Do you strive for a completely automated production process?Get in touch with us

Leave a message