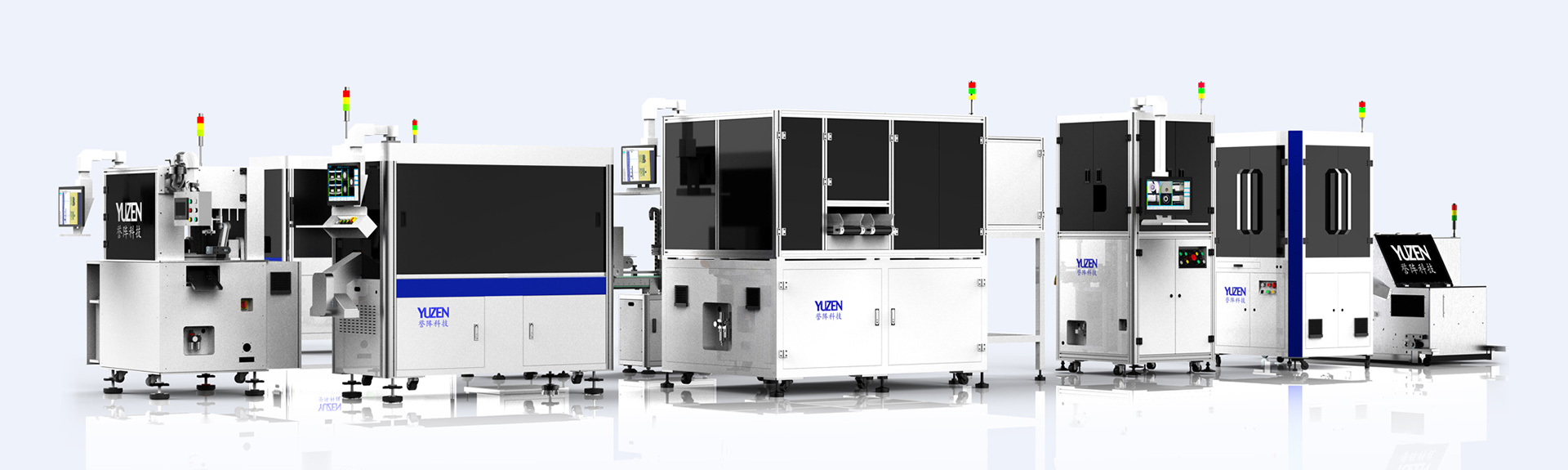

Quality inspection solutions for the

plastic packaging industry

Suzhou Yuzhen Technology Co,Ltd. is a high-tech enterprise integrating R&Dproduction, sales and service, which focuses on the intelligence and automation otproduct quality inspection in the packaging industry.

The core team has more than15 vears of experience in the machine vision industry and is good at a host Controand process multiple industrial cameras to work simutaneously.

Find more about us

The core team has more than15 vears of experience in the machine vision industry and is good at a host Controand process multiple industrial cameras to work simutaneously.

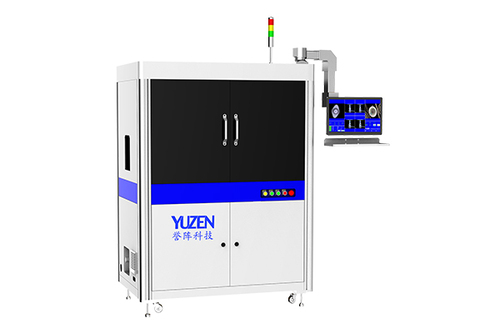

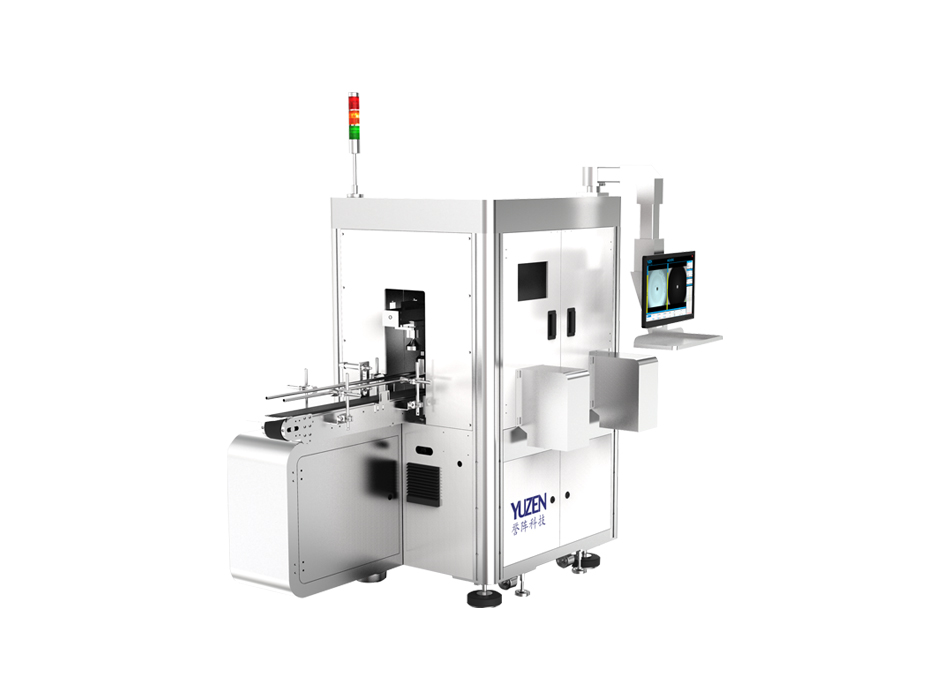

Our Products

We offer vision inspection solutions for a huge range of plastic packaging. You cannot find the right vision system for your product?

Just contact us for a customized solution.

Just contact us for a customized solution.

Solutions for your industry

From industrial cameras to algorithmic platforms, machine vision products give intelligent devices the "wise eye" to dramatically improve efficiency and accuracy, reinventing your productivity at a time of change in smart manufacturing.

Get to know our sales team

Our sales managers will support you on your way to your individual inspection solution.

They listen to your needs and requirements, think in an entrepreneurial way, act strategically and keep an eye on your goals.

Our sales managers

They listen to your needs and requirements, think in an entrepreneurial way, act strategically and keep an eye on your goals.

Global market

Our products have been sold in more than 10 countries.

● 99% overall customer satisfaction

● Core team with 15 years of experience in the machine vision industry

● More than 220 service recipients;

● Completed more than 1,200+ successful visual inspection projects

● 99% overall customer satisfaction

● Core team with 15 years of experience in the machine vision industry

● More than 220 service recipients;

● Completed more than 1,200+ successful visual inspection projects

Get in touch with us,write us a message